Bamboo poles

Dried bamboo poles are not very flexible.

While there is a degree of flex (depending on the species), bamboo architecture in places like Bali are constructed using recently harvested bamboo. The green poles are dried and set into specific shapes, which is how bamboo bridges are made, for example.

Each bamboo pole is unique, so an exact figure cannot be given. Tapering varies a lot between species, with some of the thinner poles tapering down as much as 60%.

We try our best to stock quality poles that do not have extreme tapering (we expect an average of around 30%), but as bamboo is a natural product and there is no way to control nature and tapering, any projects that have a focus on diameter need to factor this in – perhaps by ordering the next size up.

For projects requiring poles that are less likely to taper, we recommend the Guadua bamboo.

Unfortunately not.

Often, bamboo poles are not perfectly cylindrical – wide at the base and tapering towards the top. Each pole is unique and the degree of tapering can also depend on the species. Wall thickness and node size also vary.

If ordering for a project requiring an exact internal diameter, we recommend going for a pole a few sizes up.

Very strong. Research has shown Guadua bamboo to have a similar tensile strength to steel and, as such, it is the world’s strongest bamboo.

Our friends over at Guaduabamboo.com in Colombia have a great page summarising research into the strength of their native bamboo, Guadua, citing extensive research conducted by the Larenstein University in The Netherlands.

On the page you will discover the mechanical properties, density, Janka hardness, and strength MOE (Modulus of elasticity) of Guadua bamboo, in comparison to Moso bamboo.

Click here to see the Guadua Bamboo research

No, unfortunately. This is down to current UK building & planning regulations surrounding commercial construction.

There are many people such as architects and university professors in talks with the government with the goal of getting bamboo approved within the construction industry (as it is in countries where bamboo grows).

We sell many bamboo poles for foundation piling, and the bamboo for this application appears to be growing. Elsewhere, bamboo is used for small structures and art installations. The likes of Bamboology’s sculptures and Atlas Domes’ geodesic domes for events are great examples.

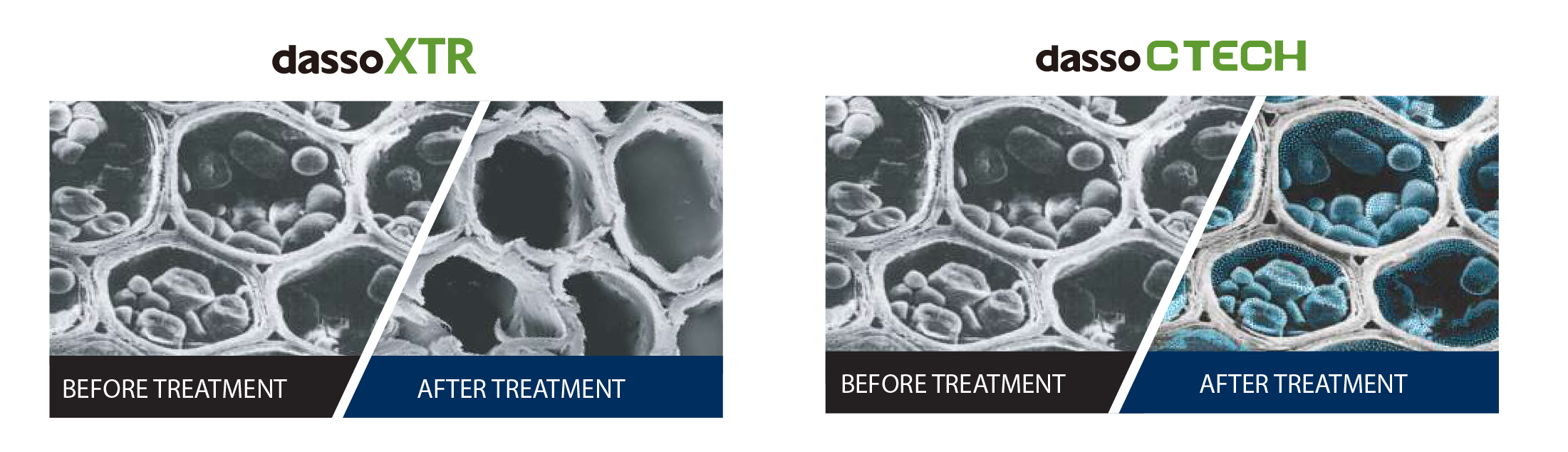

Most of our bamboo is untreated.

On products that have been stated as treated, the bamboo is cured in Borax acid and salts. This is so the product can be legally shipped worldwide from the source forest.

Click here to view more information on the safety of our treated products.

We recommend a fine-toothed wood saw + medium grit sand paper to smooth the rough edges.

We cut the bamboo poles in-house using a circular chop saw and a band saw. To minimise fraying of the pole, the key is to cut slow.

Old methods of cutting bamboo featured a machete and hammer (though we wouldn’t recommend this!).

This depends on the bamboo species.

- Bamboo from our Natural Bamboo Poles category have a waxy exterior that resists application of paint.

- The same applies for the Dark Bamboo Poles category, aside from the larger sized poles (60/80mm and up) as they have a naturally matte exterior.

- Guadua bamboo has a matte exterior and customers have had success painting their bamboo.