Surface Design Show 2022: Reflections on sustainable materials

Last month, UK Bamboo had the pleasure of attending the Surface Design Show at the Business Design Centre in London.

Over 150 exhibitors were in attendance, with the event bringing together exhibitors from all over the world – from Japanese master tile ceramicists (Raven) and Italian marble specialists (Elite Stone), to many UK-based brands and forward-thinkers (such as DF Richards wood veneers) – to showcase the latest innovations and surface design trends. The event featured a strong focus on sustainability, with the theme ‘A Sense of Place’ highlighting how the planet’s wellbeing should be at the heart of all decision making when it comes to surface design.

For decades, the economics of surface materials (and to an extent, all manufactured products) have dominated decision making and has been the primary driving force behind why some materials are so much more widespread than others. Plastic is cheap, easy to mass-produce, malleable to any shape, and is highly durable. However, some plastics take centuries to decompose and never fully break down. “Microplastics have moved into virtually every crevice on Earth,” reports National Geographic. With the growing climate crisis, there is a steady wave of change on the horizon as increasingly businesses are becoming more environmentally conscious and thinking beyond profits to how we can preserve the planet for future generations. Profitable business and caring for the environment are not mutually exclusive, and some global brands like Nestlé and BrewDog are fantastic examples of this with their reforestation projects.

The vast array of materials showcased at the Surface Design Show further reflected how both suppliers and consumers are becoming more environmentally conscious. Several products particularly stood out, and neatly summarised what sustainability means (more on this in the debate notes below).

3 surface design trailblazers that stood out for us:

Architextural

A lot of waste is generated by interior refurbishments and this brand’s self-adhesive architectural films provides a solution to this. Virtually any surface can be upcycled following the fitting of the wrap, achieving a refurbished look without the environmental impact a complete refurb would have. It was fascinating to touch the different wraps to discover that they felt like the real thing. The central table of the stand was wrapped in a faux leather film to achieve a high-end look, and you would never know that was not how the table looked originally!

Smile Plastics

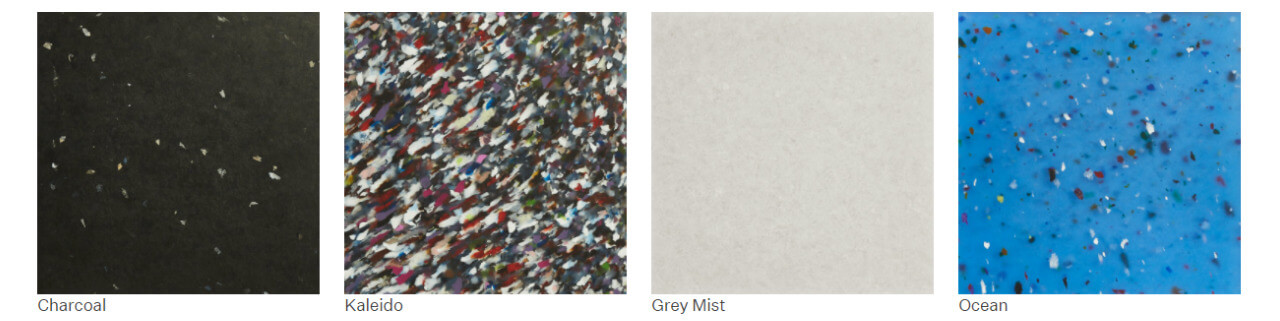

Discarded plastic have a bad reputation and this company is flipping the narrative on what “waste” means by processing post-industrial, commercial and single-use plastics, to manufacture a range of decorative surface panels.

“We include distinct traces of the plastics’ origins in their new life to create a narrative around the materials. This can take shape as flecks of foil from original yogurt port lids or text and barcodes from plastic packaging. The details draw you in, letting you know quietly how those materials came to be” – Smile Plastics

The end result is a 100% recycled and recyclable product. The company’s buy-back scheme creates a circular product lifecycle. Offcuts are an opportunity and panels that are no longer required can be sold back to the manufacturer – an innovative solution to the plastic problem.

Emily Hatton Surface Design

Similar to Smile Plastics, waste is not the end for Emily Hatton. Her abstract waste experimental series explores how waste materials can benefit design. The 3D wall tiles on display combined eco-resin (jesmonite) with organic waste materials, such as eggshells and grass cuttings, to create unique surface patterns and textures. The bold colours achieved make these wall tiles a statement piece for an interior that would work well as a feature wall (and a talking point for sustainability).

The debate of the event: Natural Vs. Synthetic materials

The main stage at the Surface Design Show hosted a very thought-provoking industry debate, “Natural vs Synthetic Materials vs Application,” between Smile Plastics and Evan James Design. A key takeaway from this talk was how it is paramount that surface designers and buyers consider the product’s lifecycle – the journey from start to finish. Smile’s products can be infinitely recycled (a characteristic shared with metal and glass), while Evan James uses FSC-certified timber to create a surface system that “fosters endless possibilities of pattern, colour and texture, which are not fixed upon installation.” For Evan James, “the design can be changed after installation in response to the demands and desires of the setting.” For both surface designers, the natural vs synthetic argument does not apply. It is all about application. And this made us reflect on our own products.

Bamboo awaiting its debut

While there was a large focus on harnessing the untapped power of waste materials, natural materials also have their own fantastic properties for sustainable surface design. A handful of wood suppliers were exhibitors at the event, showcasing veneers, flooring, and acoustic panels. As a supplier of bamboo, it was interesting to see bamboo not making an appearance, given its sustainable properties and increasing popularity (Ikea now sell a bamboo kitchen, FRÖJERED, for example).

Bamboo is one of the fastest growing plants on the planet with a plantation taking 10 years to reach maturity for harvesting – a lot shorter than other woods (European oak requires at least 80 years before harvesting). The rapid growth means bamboo is infinitely scalable with demand. The plant sequesters carbon within its rhizomatic root system and cutting down the poles doesn’t harm the overall plant. Bamboo forests managed in a careful way can provide both an important carbon sink and a source of wood. It is undeniable that shipping from the source country (e.g., China) does carry a hefty carbon footprint; however, research conducted by INBAR and MOSO International has explored this in a 50-page report (see: The Environmental Impact of Industrial Bamboo Products). “In terms of annual yield of the end product […] it can be concluded that bamboo is one of the best performing renewable resources around, especially if used as a semi-finished material in a durable application” (p49), writes INBAR researcher P. van der Lugt, PhD. Although bamboo cannot be infinitely recycled like plastic, the qualities it does have makes the material a game changer in the surface design field.

Conclusion

For UK Bamboo, we are proud to work with this product and some fantastic clients that recognise the sustainable and durable properties of bamboo. Sheffield Sustainable Kitchens and Zero Kitchens, for example, use our FSC-certified bamboo boards as kitchen worktops. Interior designers have used our bamboo wallpaper and wall tiles to introduce a warm, vibrant and modern look to interiors.

We very much enjoyed the Surface Design Show and look forward to attending next year, perhaps as an exhibitor, to introduce bamboo into the eco interior design mix.